The industrial sector has always relied on the connections between machines and processes. But today’s manufacturing and process plants are witnessing a fundamental shift in how these connections work—and what they connect to.

Walk through a modern facility and you’ll see the physical infrastructure that’s been there for decades. What you won’t see is the invisible nervous system now running through it: a web of digital technologies linking shop floor equipment to enterprise systems, creating what industry professionals call the edge-to-enterprise ecosystem.

Beyond Isolated Systems

For years, industrial automation meant programmable logic controllers (PLCs) and SCADA systems managing individual processes. These systems did their jobs well, but they operated in isolation. Production data stayed on the factory floor. Business intelligence lived in enterprise systems. Engineering worked in its own software environment.

Industry 4.0 has changed this landscape. Forward-thinking operations now view automation as the foundation for an integrated ecosystem where operational technology (OT) and information technology (IT) converge. This isn’t about replacing existing infrastructure—it’s about integrating it into a smarter, more connected system.

The Power of Edge Intelligence

Edge technologies—sensors, controllers, gateways, and edge computing devices—capture what’s happening where value creation occurs. The real power behind these technologies emerges when edge intelligence enables immediate decision-making while simultaneously feeding information upstream to enterprise systems.

A temperature sensor doesn’t just report a reading anymore. It can trigger an automated response at the edge while alerting maintenance systems, updating asset management databases, and informing supply chain planning. This bidirectional flow creates something greater than the sum of its parts.

Digital Twins: Risk Mitigation Through Simulation

Perhaps no technology better illustrates the power of this ecosystem approach than the digital twin—a virtual replica of physical assets, processes, or systems, continuously updated with real-time data.

Engineers can test scenarios before implementing them on actual equipment. Operators can visualize what’s happening inside vessels and pipelines that can’t be directly observed. Maintenance teams can predict failures before they occur.

For risk management, this is transformative. Instead of scheduling shutdowns based on fixed intervals or waiting for equipment to fail, teams can simulate different scenarios and understand their implications. What happens if we increase throughput? How will systems respond to temperature changes? Can we extend this maintenance cycle safely?

The digital twin answers these questions without putting physical assets or people at risk.

Making It Work Together

Industrial facilities often run on equipment from dozens of vendors, installed across decades, speaking different protocols. Creating harmony requires both technical standards and strategic thinking.

Consider maintenance optimization, which requires condition monitoring data from edge sensors, work orders from enterprise systems, parts inventory from supply chain databases, equipment specifications from engineering systems, and historical performance data.

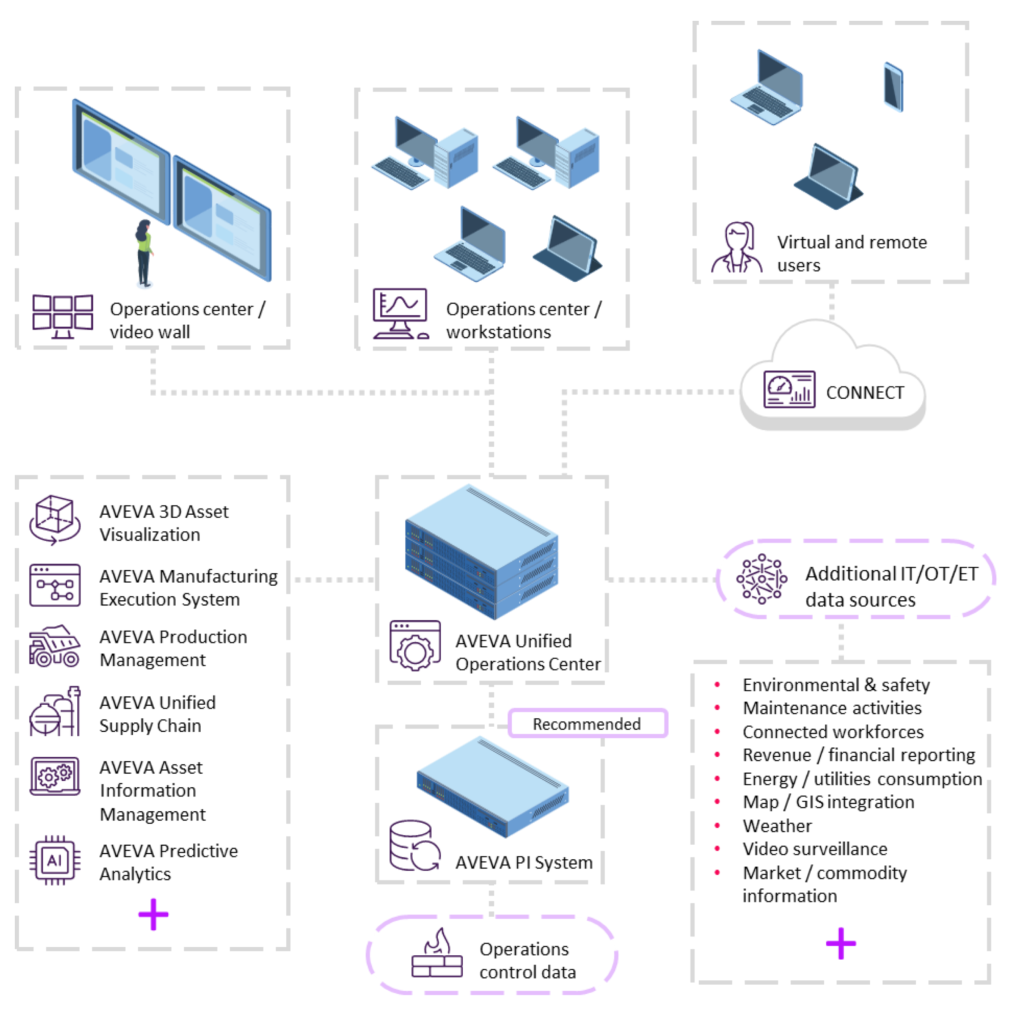

No single system owns this workflow — but when integrated through solutions like AVEVA Unified Operations Center and AVEVA MES, these systems collaborate seamlessly to drive smarter maintenance and dramatically improve equipment reliability.

The Human Factor

The most important integration happens between systems and people. A maintenance technician shouldn’t need three different logins to complete a work order. A plant manager shouldn’t reconcile conflicting data from multiple systems.

When integration is done right, users don’t think about which system holds which data—they simply access what they need, when they need it.

Building for Tomorrow

The industrial facilities being designed today will operate for fifty years or more. Successful organizations build their edge-to-enterprise ecosystems on flexible foundations: standard protocols, modular architectures, and data models that can evolve as needs change.

They recognize that integration is never truly finished. New technologies will emerge, business needs will shift, and facilities will expand. The ecosystem needs to accommodate this evolution without requiring complete rebuilds.

The Path Forward

Digital twins reduce risk through virtual testing and predictive insights. Edge intelligence enables faster responses and better local decision-making. Enterprise integration ensures operational excellence connects directly to business outcomes.

For industrial operations, the question is no longer whether to embrace this integration, but how quickly they can build the capabilities needed to compete in an increasingly digital world. The companies thriving in this environment are the ones that’ve learned to make their entire technology ecosystem work as one.